Types of fuses will be a benefit for us to learn before buying and using them. For every application, there will be different fuse to use.

What is a Fuse?

A fuse is an electrical, electronic, or mechanical device that protects circuits from overcurrent, overload, and ensures circuit protection. Thomas Alva Edison devised the electric fuse in 1890.

Fuse comes in a variety of shapes and sizes, but they all serve the same purpose. The numerous varieties of fuses, their manufacture, working and operation, and their application in various electronics and electrical systems will be discussed in this article.

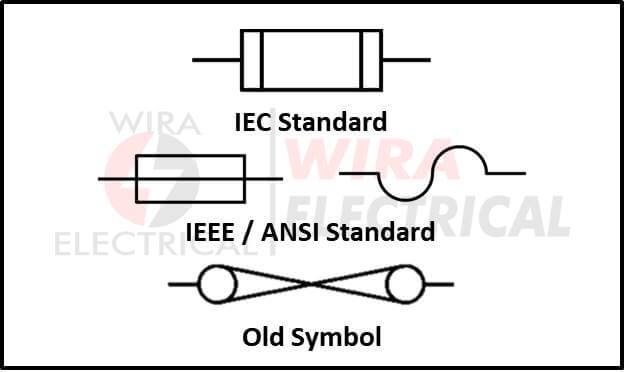

What is the Fuse Symbol?

There are electrical symbols for fuse from different standards:

Why do we Need Fuses?

These are used to protect home equipment from harm caused by high current or overload. When we utilize a fuse in our homes, electrical problems in the wiring are prevented, and the appliances are not damaged by wire fires.

When a fuse is blown or damaged, an abrupt sparkle occurs, which can cause immediate damage to your home appliances. That is one of the main reasons why we need different types of fuses to protect our home appliances from damage.

For circuit protection, fuses come in a variety of shapes and sizes.

Amperes are the most common unit of measurement for fuses. Despite the fact that their operation is based on the self-generation of heat in the presence of additional current via their own created electrical resistance.

This is usually accomplished by keeping the fuse wire length as low as feasible. Because wire length is independent of current rating values, the shortest wire length imposes the shortest resistance value.

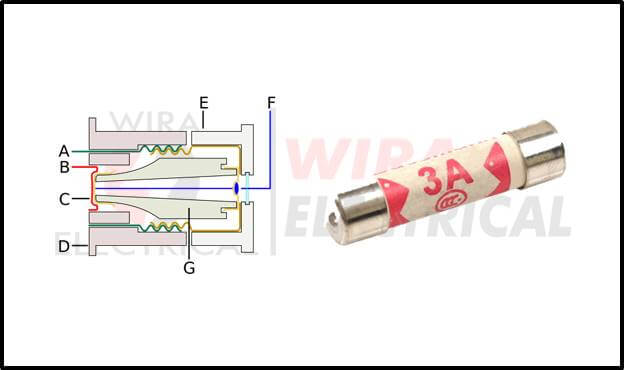

Construction of a Fuse

A common fuse is made up of a low-resistance metallic wire that is encased in a non-flammable substance. It is used to connect and install in series with a circuit and device that needs to be protected from short circuit and over current.

If the fuse and circuit breaker are not present, the electrical appliance may be damaged because they are unable to handle the excessive current according to their rating limits.

How Does a Fuse Work?

The basic function of a fuse is to break the circuit if it draws more current than it should, preventing harm from short circuits.

The most basic types of fuses are made up of a resistive element that has been carefully chosen for its melting point. When a current runs through this element, a minor voltage drop is formed across the element (small enough that the circuit downstream is unaffected), and some power is dissipated as heat.

As a result, the element’s temperature rises. This temperature increase is insufficient to melt the filament at normal currents. The melting point is quickly reached if the current draw exceeds the fuse rated current. The circuit is disrupted when the resistive element melts.

The rated current is determined by the thickness and length of the resistive element.

To generate predictable trip currents, fuse elements are constructed of zinc, copper, silver, aluminum, or other alloys. Over time, the element must not oxidize or corrode.

A fuse’s functioning concept is based on the “Heating Effect of Current,” which states that whenever a short circuit, overcurrent, or mismatched load connection occurs, the fuse’s thin wire melts due to the heat generated by the heavy current passing through it.

As a result, the power supply to the linked system is disconnected. Fuse wire is only a very low resistance component in normal circuit operation, and it has no effect on the normal operation of the system connected to the power source.

How to Choose a Fuse Rating

Different considerations and surroundings must be considered when choosing the right fuse and its rated size for electrical products. However, the formula below demonstrates how to select the proper fuse size.

Fuse Rating = ( Power / Voltage ) x 1.25

For example, you have to find the right size of fuse for a 10A two pin socket.

(1000W / 230V ) x 1.25 = 5.4A

The power rating in the aforementioned example is 1kW, which may be managed via the 2 pin socket, and the main supply voltage is single phase 230V AC (120V AC in US).

However, for safe and reliable operation of the circuit, you should use the maximum fuse rating, which is 6A instead of 5.4A.

Read also : low pass vs high pass filter

Characteristics of Fuses

Different types of fuses can be listed on the following characteristics:

- Voltage Rating of Fuse

- Current Rating of Fuse

- Response Characteristic

- Packaging Size

- I2t Value of Fuse

- Classification of function

The following is a basic description of the categories mentioned above.

Voltage Rating of Fuse

There is a maximum voltage rating that a fuse can safely take, therefore expect the current capacity of current. Different quantities of isolation are necessary in different fuses working on different voltage levels.

For example, a fuse intended for 32 volts cannot be used with 220 volts. A fuse can be classified as HV (High Voltage), LV (Low Voltage), or Miniature Fuses depending on the voltage rating.

Current Rating of Fuse

The amount of current that a fuse can easily carry without breaking the circuit is known as its current carrying capability.

Capacity to break:

Breaking Capacity is the greatest current that may be safely stopped by the fuse and should be more than the potential short circuit current.

Response Characteristic

The amount of electricity running through the fuse’s wire determines how quickly it blows. The faster the response time, the higher the current flowing through the wire.

The response time for an overcurrent incident is represented by the response characteristic. Ultra fast fuses, also known as Fast fuses, are fuses that respond quickly to an overcurrent condition. They’re employed in a lot of semiconductor devices because they’re easily harmed by too much current.

Packaging Size

As previously stated, AC and DC fuses have slightly different packaging types, and different applications necessitate the use of different packages in the circuit.

Marking, temperature derating, voltage drop, and speed are some of the additional elements and parameters.

I2t Value of Fuse

The I2t words referred to fuses that are commonly employed in short circuit situations. When the electrical fault is cleared by the fuse element, it is the amount of energy carried by the fuse element.

Classification of Function

Fuses are categorized as “One Time Only Fuse,” “Resettable Fuse (like an MCB),” “Current Limiting and Non-Current Limiting Fuses,” and “Current Limiting and Non-Current Limiting Fuses” based on their application.

When an over current, overload, or mismatched load connect event happens, the user must manually change the fuses. Switch fuses are inexpensive and widely utilized in practically all electronics and electrical systems.

When a problem arises in the system, the Resettable fuse, on the other hand, automatically resets after the operation.

Current-limiting fuses produce high resistance for a short time, whereas non-current-limiting fuses produce an arc in the event of high current flow, interrupting and limiting current in related and connected circuits.

Next is types of fuses.

Types of Fuses

Different types of fuses are available on the market, and they can be classified based on many factors.

Different varieties of fuses are available on the market, and they can be classified based on many factors.

Types of Fuses : DC fuses

When the metallic wire melts in a DC system due to the heat generated by the excess current, an arc is formed, which is exceedingly difficult to extinguish due to the DC constant value.

So, in order to lessen fuse arcing, DC fuses are somewhat larger than AC fuses, increasing the distance between the electrodes and thereby reducing fuse arcing.

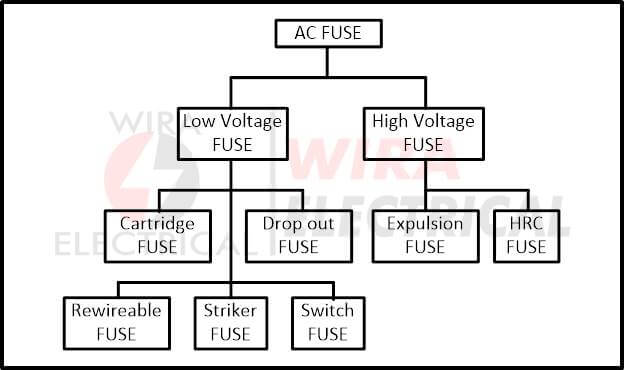

Types of Fuses : AC fuses

In contrast to DC, voltage with a 60Hz or 50Hz frequency increases its amplitude from zero to 60 times every second in an AC system, making arcs easier to extinguish. As a result, AC fuses are a little smaller in size than DC fuses.

Fuses can also be classified based on whether they operate one time or several times.

Types of Fuses : High voltage fuses

In power systems, high voltage (HV) fuses are used to protect the power transformer, distribution transformers, and instrument transformers, among other things, when circuit breakers are unable to protect the system. Fuse with a rating of more than 1500V and up to 13kV are known as high voltage fuses.

High-voltage fuse elements are typically composed of copper, silver, or tin. In the case of expulsion type HV (High Voltage) Fuses, the fuse link chamber may be filled with boric acid.

Types of Fuses : Cartridge fuses

Cartridge fuses are used to protect electrical appliances with high voltage ratings and currents, such as motors, air conditioners, refrigerators, and pumps. They are commonly utilized in industrial, commercial and residential distribution panels, and are available up to 600A and 600V AC.

Cartridge fuses come in two varieties.

- Heavy-duty cartridge fuses with time delay and

- General-purpose fuses with no time delay. Both come in a range of voltages from 250 to 600 volts, and the rating can be found on the end cap or knife blade.

Cartridge Fuses are contained in a base and are further separated into Link type and D type cartridge fuses.

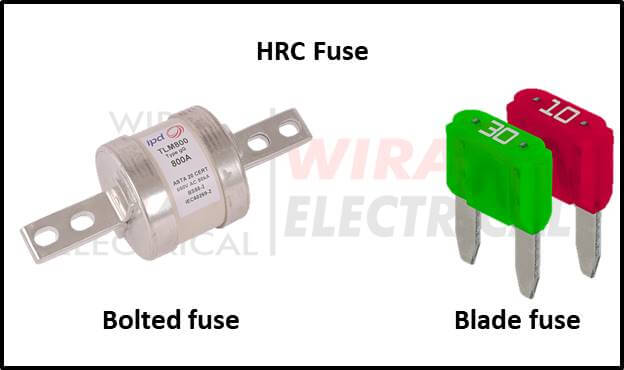

Types of Fuses : HRC (High Rupturing Capacity) fuses

We’ve already gone through the manufacture, operation, and applications of HRC fuses (High Rupturing Capacity fuses).

It also discusses numerous types of HRC fuses, such as DIN, NH, Blade, Liquid Type HRC Fuse, Expulsion Type HV Fuse, and its benefits and drawbacks.

HRC fuses (High Rupture Current): HRC fuses are cartridge-type fuses with a clear steatite envelope (magnesium silicate). The arc extinguishing agent in the fuse is quartz powder (or, in the case of liquid-filled HRC fuses, a non-conducting liquid like mineral oil).

These fuses are used to protect against extremely high fault currents.

High Rupturing Capacity fuses (HRC) are also known as link-type cartridge fuses. HRC fuses have a high capacity for breaking. On both sides, it features two metal ends. The use of powdered pure quartz to fill the fuse functions as an arc extinguishing agent. The fuse element is made of either silver or copper.

The short circuit current is carried by the fuse element for a long time. An unknown defect will melt and open the circuit at this period. A high resistance is formed by the chemical reaction between a silver vapor and the filling powder, which aids in the quenching of the arc.

Using two or more silver wires in parallel increases the fuse’s breaking capacity. This sort of fuse is separated into two types: blade type fuses and bolt down type fuses. Blade type fuses are the most reliable.

Blade fuses are also referred to as spade fuses or plug-in fuses. This fuse is used by automotive OEMs for vehicle circuit protection and can resist high temperatures.

Bolt down fuses, on the other hand, are special-purpose fuses designed for diesel vehicles and are not suitable for automotive trucks.

Types of Fuses : Expulsion fuses

Because of their low cost, expulsion type fuses are commonly employed to protect feeders and transformers. It has a rupturing capacity of up to 250 MVA and is designed for 11kV. A hollow open-ended tube composed of synthetic resin-bonded paper is used in this sort of fuse.

The fuse elements are put in the tubes, which are then connected to appropriate fittings at both ends. The arc-producing material is blown out of the tube’s inner covering, and the gasses created extinguish the arc.

These fuses are packed with substances like boric acid, which when heated, create gasses. The arc is extinguished by these glasses, which are ejected from the fuse’s ends. Copper, tin, or silver are used to make the fuse element.

Types of Fuses : Drop out fuses

They have a spring-loaded lever arm that retracts when a fault occurs and must be rewired and reinstalled for regular operation to continue. Drop out fuses are a type of expulsion fuse.

Types of Fuses : Switch fuses

High current fuses can be connected or disconnected manually using a handle.

Types of Fuses : Striker fuses

They have a spring-loaded lever arm that retracts when a fault occurs, and must be rewired and reinstalled in order to resume normal performance.

A sort of ejection fuse is an expulsion fuse.

Types of Fuses : Rewireable fuses

The most well-known kit-kat fuse (also known as rewireable fuse) is mostly utilized in industrial and residential electrical wiring for low-current applications in Low Voltage (LV) systems.

There are two essential pieces to a rewireable fuse. The inner fuse element is a fuse carrier made of tinned copper, aluminum, lead, or other metals, while the base is constructed of porcelain with IN and OUT terminals that are utilized to protect the circuit.

The main benefit of a rewireable fuse is that it can be readily repaired if it is blown due to a short circuit or excessive current melting the fuse parts. Simply connect another fuse element wire with the same rating as the previous one.

Types of Fuses : D fuses

An adapter ring, base, cap, and cartridge are all included in the D-Types fuse. The fuse base is attached to the fuse cap, which houses the cartridge. When the cartridge’s tip makes contact with the fuse link conductor, the circuit is complete.

Types of Fuses : SMD fuses

SMD Fuses (Surface Mount Device, derived from SMT = Surface Mount Technology) are chip-type fuses (also known as electronic fuses) used in DC power applications such as hard drives, DVD players, cameras, cell phones, and other devices where space is limited. SMD fuses are small and difficult to replace.

Types of Fuses : Thermal fuses

As previously stated, a thermal fuse is a one-time use fuse. They are temperature sensitive fuses with a temperature sensitive alloy fuse element. Thermal Cutouts (TCO) or Thermal Links are the terms used to describe them.

The fuse element of a thermal fuse contains a mechanical spring contact that is ordinarily closed. When large currents run through the elements of the fuse as a result of an overcurrent or a short circuit, the fuse elements melt, releasing the spring mechanism and preventing an arc and fire while also protecting the associated circuit.

Types of Fuses : Semiconductor fuses

Semiconductors are employed for ultrafast fuses because the power dissipated by them grows exponentially with current flow. These fuses are commonly employed to protect semiconductor switching devices that are susceptible to even minor current spikes.

Types of Fuses : Resettable fuses

These fuses are self-resetting, as their name implies. Carbon black particles are incorporated in organic polymers in these products. Carbon black renders the mixture conductive in most cases.

Heat is generated when a large current flows, which causes the organic polymer to expand. The carbon black particles are driven apart, and conductivity drops to zero. As the temperature drops, the conductivity returns.

As a result, the fuse does not need to be replaced physically. Because resistance increases with temperature, this type of fuse is also known as a PTC (positive temperature coefficient).

A resettable fuse is a device that can be used several times before needing to be replaced. When an overcurrent event happens, they open the circuit and reconnect it after a set period of time.

The polymeric positive temperature coefficient device (PPTC, also known as a resettable fuse, poly-switch, or poly-fuse) is a passive electrical component that protects electronic circuits from short current problems.

PTC Fuse can be found in anything from computer power supplies to phone chargers. They’re especially useful in this situation because replacement is difficult. They are also employed in aerospace devices for the same reason.

In their through-hole varieties, PTCs are easily recognizable by their yellow-orange color and disc (and occasionally rectangular) shape.

Green with white markings or black with gold markings are the most common colors for SMD poly fuses. PTCs are available in almost every grade now in use.

Resettable fuses are used in situations where manually replacing fuses is difficult or impossible, such as in nuclear power plants or aircraft systems.

Applications of Fuses

Electrical and electronic fuses come in a variety of shapes and sizes, and can be used in a variety of electrical and electronic systems and applications, including:

- Home distribution boards

- Motors & Transformers

- Cell phones

- LCD monitors

- Air-conditions

- Battery packs

- Scanners

- Portable Electronics

- Power converters

- General electrical appliances and devices

- Laptops

- DVD players

- Hard disk drives

- Game systems

- Printers

- Digital cameras

Summary

A fuse is a small safety part in an electrical device or piece of machinery in the world of electronics or electrical. It is regarded as the most important component in various electrical circuits.

Many different types of fuses are available in the business and can be used to satisfy varied circuit needs.

There are various varieties of fuses available on the market, each with its own set of benefits and applications. They are self-acting braking devices for load protection. They’re also found in cable lines and motors to prevent short circuits.

Better then text book

In easy way study